SERVICES

Engineering and Project

Metalogalva is active in the design and manufacture of metal structures. It has a highly qualified Technical Department with several engineers capable of providing global and innovative engineering solutions, particularly in the metal-mechanical construction segments, as well as testing prototypes in terms of assembly and/or structural strength.

The products developed have applications in various fields of activity, including energy, lighting, telecommunications, road and rail and renewables.

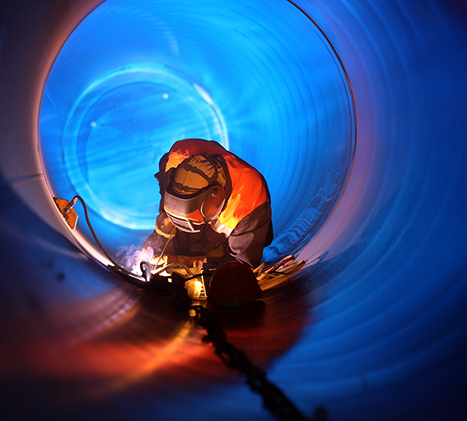

Manufacturing

As a result of an extensive experience acquired over the years, Metalogalva uses methodologies and efficient manufacturing techniques, which complemented with the ability of experienced workers, is reflected in the creation of high quality products.

Concerning to the materials, construction details and finishes, the requirement is high, in order to offer customers a product of great confidence in the structure and functionality.

To optimize the technical means Metalogalva offers the following services:

Longitudinal and transverse cutting of coil sheet, Sheet cutting (guillotine, laser, oxyfuel cutting, and plasma), Profile cutting and drilling, Sheet bending, Longitudinal welding (laser, MIG MAG, and submerged arc), Automatic welding, Stamping, Bending, Profiling, Turning, and Machining.

Hot Dip Galvanizing

The longevity, resulting from applications of an anti-corrosive hot dip galvanizing process, is one of the characteristics of the products Metalogalva.

Treatment of electroplating, which is characterized by a metallic bonding between the steel part to galvanize and zinc, specially by immersing the piece in a bath of molten zinc at aproximately 450ºC, confers to the products made from steel, a corrosion resistance which is not reachable by any other process, and which complements the quality and durability of them.

The Metalogalva is equipped with a modern galvanizing equipments for hot dips, where, in addition to galvanizing their own production, also provides this service to external clients. The equipments can process parts with measures to 12500x1850x2600mm.

Installed capacity: 60.000 t/year;

Maximum Capacity Weight Parts: 10 t;

Maximum length: 18 m (other measures under/request);

Relevant/Special Facts: Galvanizing by double immersion; Centrifuge Galvanizing;

WHY GALVANIZING?

Painting

DUPLEX SYSTEM

The product exposure to an environment whose characteristics advise a supplement to the corrosion, or to respond to requests for esthetics, the Metalogalva enforces a duplex system, characterized by the application of paint on parts zinc coated paint booth with a controlled environment (liquid or electrostatic paiting).

The application of duplex systems follows a judicious choice of paint schemes and the preparation of specific requirements.

COATECTION COMPLETE

The Unit of electrostatic painting is totally automatic, in an area of implementation of approximately 1700m², allowing the painting of parts with lengths up to 12,5m. This painting process is intended to provide to the steel pieces a polymer term hardened coating, by electrostatic sprinkling, and with a final homogeneous and resistant finishing.

Metalogalva System COATECTION, offers a choice between smooth or aerated finishes, as well as special options of protection against extremely corrosive environments and anti-graffiti and anti-sticker protection. It offers different paint schemes for different grades of durability, different categories of corrosivity and desired coating thickness, in a wide range of colors.

Installed capacity: 300.000 m²/ano

Maximum Load per rack: 1500kg

Useful paint dimensions: 12500x800x1900 mm (L x W x H)

Logístic

Through its extensive fleet and the versatility of its many specialized partners, Metalogalva ensures the safe transport of any load regardless of size or weight.

Whenever required makes the integrated management of all means of transport by road, rail, sea or air, from the origin to destination, ensuring, through its network of partners, the logistics organization.